| HOME |

ABOUT |

FACILITIES

EXPERTISE |

VANADIUM PROCESSING |

ZERO CARBON IRON MAKING |

TANTALUM TUNGSTEN |

VANADIUM ELECTROLYTE |

RARE

EARTH RECYCLING |

ELECTRODES |

ELECTROLYZERS |

PATENTS |

NEWS |

LINKS |

CONTACT |

Français Français |

|

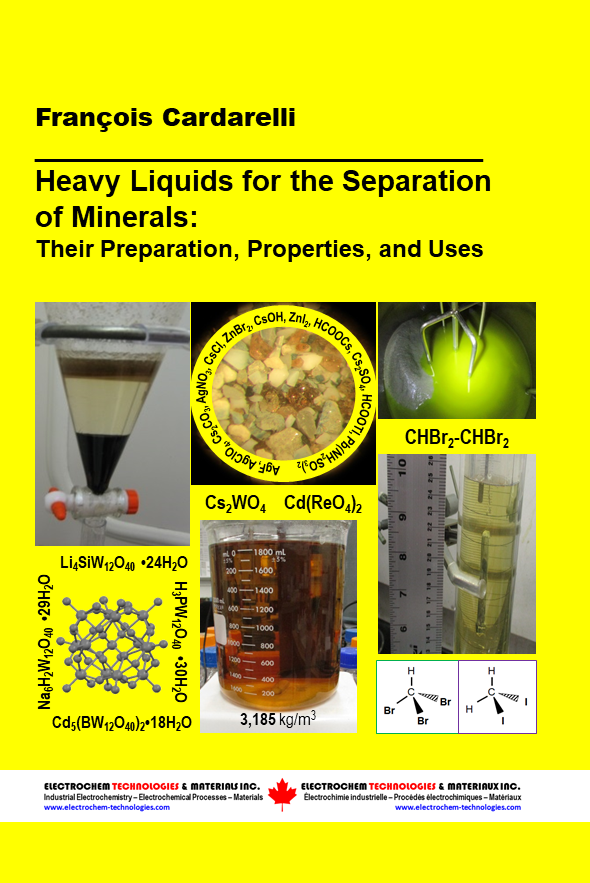

Heavy Liquids for the Separation of

Minerals: Their Preparation, Properties, and Uses

Author:

François Cardarelli

Publisher:

Electrochem Technologies & Materials Inc., Montréal, Canada

ISNI (International Standard Name Identifier): 0000 0005 1247 3654 Pages :

xxiv, 537 pages, 285

tables, 76 figures B/W and Color

Format: 6 inches x 9 inches (15.24 cm x 22.86 cm) Library of Congress Catalog No.: n.a. Canadian Classification Number: n.a. ISBN

978-1-7775769-6-7 Softcover

March 24, 2025 ASIN: 1777576962

ISBN 978‐1‐7775769‐7‐4

eBook

March 24, 2025 ASIN: BOF2CTCF8W

For purchase visit amazon bookstores: www.amazon.ca www.amazon.de | amazon.se | amazon.com.br | amazon.com.au | www.amazon.co.jp Also available from these booksellers: Google Play | GoogleBooks This

monograph is primarily intended to describe the main physical

and

chemical properties of heavy organic liquids (e.g., bromoform, tetrabromoethane, diiodomethane), dense aqueous

solutions of

salts of inorganic acids

(e.g., halides, sulfates, nitrates, perchlorates, molybdates,

tungstates, metatungstates, polytungstates, polyoxometalates,

tantalates, perrhenates, etc.), and salts of organic acids (e.g, formates, acetates, oxalates, malonates, benzoates, salicylates, citrates, etc.) and heavy suspensions used in mineralogy, gemology, mining, metallurgy, and chemistry for the separation by gravity of minerals, metallic ores,

graphite, coal

macerals, fossils, diamonds and gemstones along with plastics, glass, ceramics

and

other synthetic materials. Moreover dense solutions of cesium and rubidium salts used in

biology

for the separation of nucleic acids, and other biological molecules of

interest

by centrifugation using density gradients are also described. For several

heavy liquids, it provides a detailed description of the laboratory

methods,

and industrial processes utilized for their preparation along with the

most efficient

recovery and recycling techniques. Moreover, when available the

occupational

health and safety information for toxic and hazardous chemicals used

as heavy liquids is also provided to ensure safe practices in the work

place. Finally, their potential utilization in others fields such as X-ray and radiography contrast agents, radiation shielding agents, non-destructive testing, water-in-salt electrolytes for energy storage applications, oil drilling fluids, ballasts and counterweights due to their high density are described. The information has been presented in such a form that mineralogists, chemists, geologists, paleontologists, biologists, metallurgists, mineral processing engineers, scientists, professors, and technologists will have access to relevant scientific and technical information supported by key data gathered from several disseminated sources. The

following topics are covered: • Dense

media separation of minerals

and ores by the sink-float method, elutriation, fluidization,

centrifugation

and density gradients; • Heavy

halogenated organic solvents; • Dense aqueous solutions of inorganic salts:

|